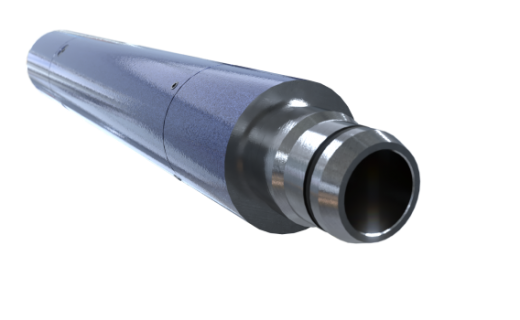

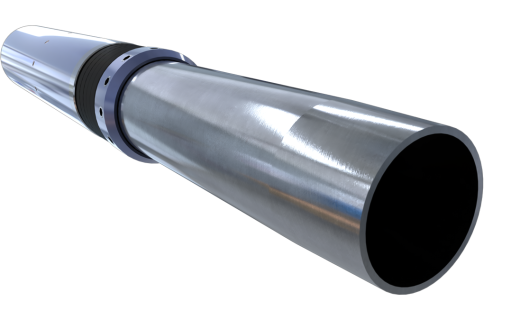

DESIGNED FOR OPERATION IN CONVENTIONAL, EXTREME, HIGH PRESSURE AND THERMAL ENVIRONMENTS UP TO 600 F, THE SOLACE HAS BEEN ENGINEERED FOR THE MOST EXTREME DEVIATED AND UNDULATED VERTICAL AND HORIZONTAL WELL APPLICATIONS.

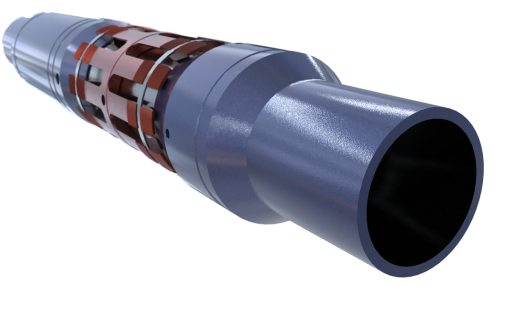

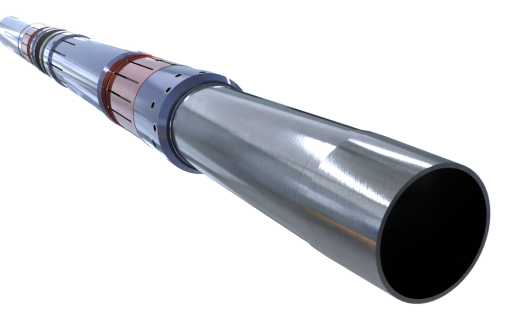

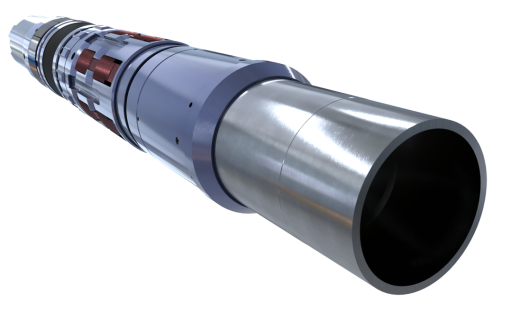

The proprietary design offers full 360 degree tubing contact with ‘state of the art’ durability, pressure maintenance and hanging/compression capacity. Our unique dual collet slip design offers bi-directional pressure and force maintenance while a one piece inner mandrel provides upper and inner bore sealing, eliminating the need for PBR or setting sleeve integral seals when used with our Tie Back Nipple.

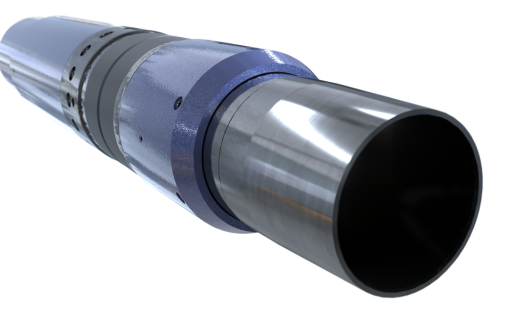

Designed with simple operation in mind, zero set down weight is required for setting, while a single downward movement engages the soft release allowing slips and seal mechanisms to release for easy extraction out of the well.

WIRE LINE SET

An available conversion kit allows the Ex-Track shear stud to release from the setting tool and adapter kit, converting the Solace to a conventional electric line setting tool.

COIL TUBING & JOINTED PIPE

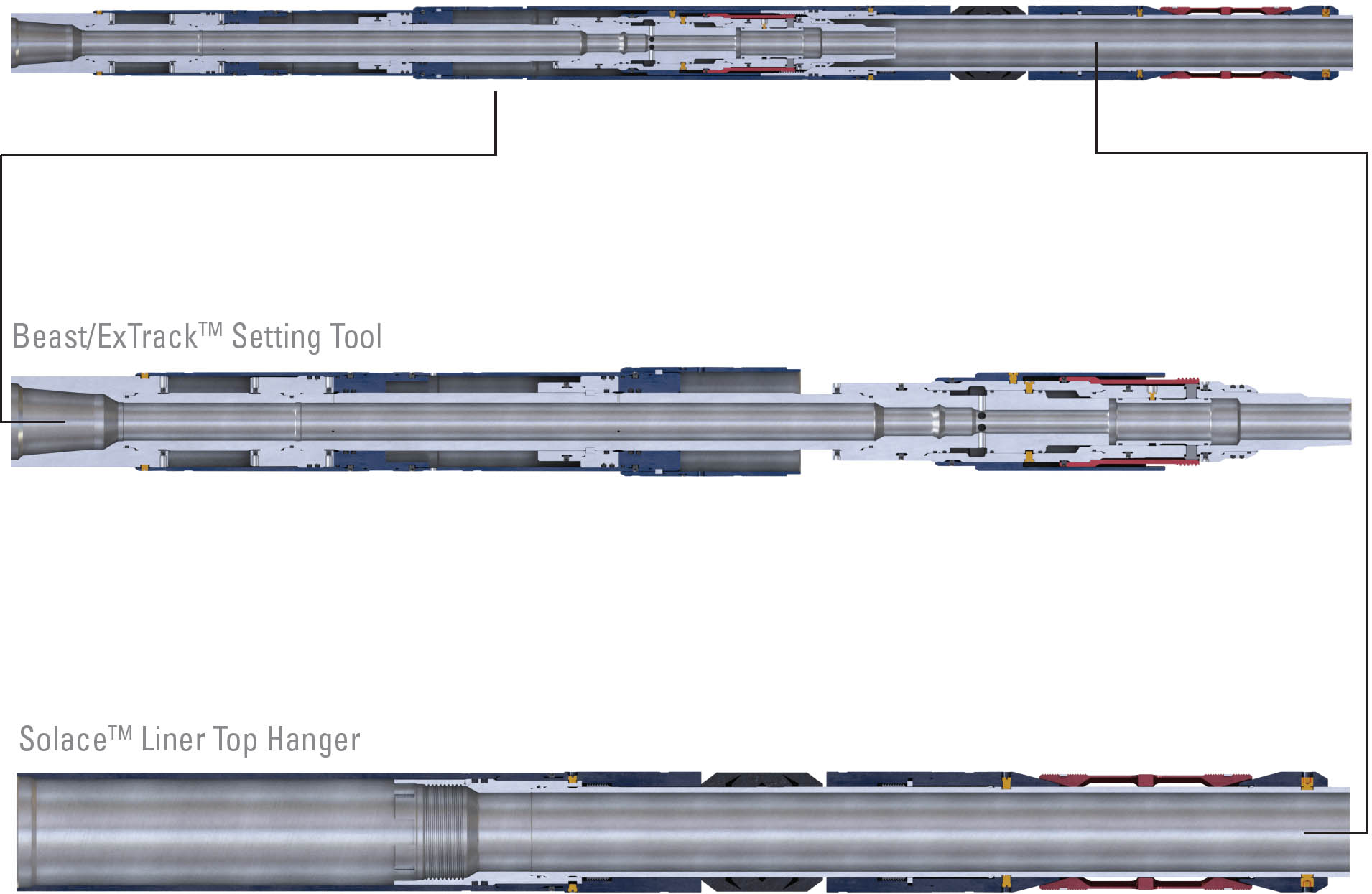

The Beast (hydraulic setting tool) combined with the Ex-Track (Setting/pulling Tool) are used to set the Solace. On retrieval, a soft release extension is supplied which is threaded to the Ex-Track tool. Stabbing into the Solace shears the soft release mechanism for easy pull and release with a secondary shear release.

FEATURES AND BENEFITS

- Completely retrievable

- Adaptable to Primary or Thermal Seals

- Primary Seal rated to 10,000 Psi.

- Thermal Seal rated to 600 F at 2,500 Psi.

- Simple, short design accomodates for hole deviation.

- Ratchet rings maintain seal stress as well as positive slip setting force

- Field adjustable shear setting

- Robust Collet type slips w/ retainers for secure run in

- Optional Internal PBR and One-Piece Mandrel

- Drill in ready, capable of rotating liners into place when required

- Can be installed bellow restriction (nipples)

- Most special clearances and ID combinations available on request

- One piece mandrel increases strength and pressure integrity

- Engineered for conventional, hazardous or thermal applications

- Soft set option with secondary shear release

- Can be installed and retrieved by wireline, coiled tubing or jointed pipe

- Metal on metal backup with secondary elastomer seal ensuring a complete seal

APPLICATIONS

- Straddling or hanging sand control liners across productive intervals

- Tubing Patch

- Pump Seating Nipple for slim hole completions

- Check Valve

- Blanking Plug

- Down Hole Choke for injection or production independent of nipples

- Production Packer c/w optional Tie Back to surface

- Gravel Packing configured for:

- one trip circulating gravel packs

- one trip squeeze gravel packs (usuallyhigh dense)