SALTEL EXPANDABLE STEEL PATCHES ARE A PERMANENT SOLUTION TO REPAIR A ZONE OF DAMAGED TUBING OR CASING, SHUT OFF UNWANTED PERFORATIONS, SEAL A LEAKING SLIDING SLEEVE, OR PERFORM OTHER REMEDIAL OPERATIONS.

Expanded with an inflatable packer downhole, the patch creates a high-pressure inner lining with minimal loss of diameter. It is made from high-quality stainless steel and has an elastomer or graphite and HT PTFE outer skin as well as a profiled sealing system. It can be run on tubing, drillpipe, or coiled tubing.

SETTING PROCEDURE

The downhole expansion tool is positioned inside the patch and the packer section is inflated enough to grip the inside of the patch. The assembly is run in a hole and once it is at depth, the packer is further inflated using pressure from the surface. The top of the patch expands and is pushed against the tubular being repaired to activate the outer seals and anchor the patch in place. The packer is subsequently deflated, run in another 3 ft [1 m], and the next section is expanded. The process is repeated until the full length has been expanded. Subsequently, the setting tools are extracted.

In addition to standard patches, several custom patches are available as described below. Various custom patches can withstand H2S, chlorides, strong acids and alkalis, nitrogen, aromatic hydrocarbons, or other aggressive chemicals and provide V0-rated gas-tight seals.

HIGH-TEMPERATURE PATCHES

HT patches are suitable for thermal wells up to 446 degF [230 degC]. They have short-term resistance to 482 degF [250 degC] and are

ISO 14310–qualified up to that temperature. Extreme high-temperature patches Extreme high-temperature patches are rated up to 662 degF and specially designed for steam-assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), and geothermal wells. They seal effectively even through thermal cycling

PREFRACTURING PATCHES

Prefracturing patches seal off frac ports (e.g., ports that opened prematurely) and withstand hydraulic fracturing pressures up to 10,000 psi [69 MPa]. These patches have a special design to ensure sealing against the irregular profile of frac ports.

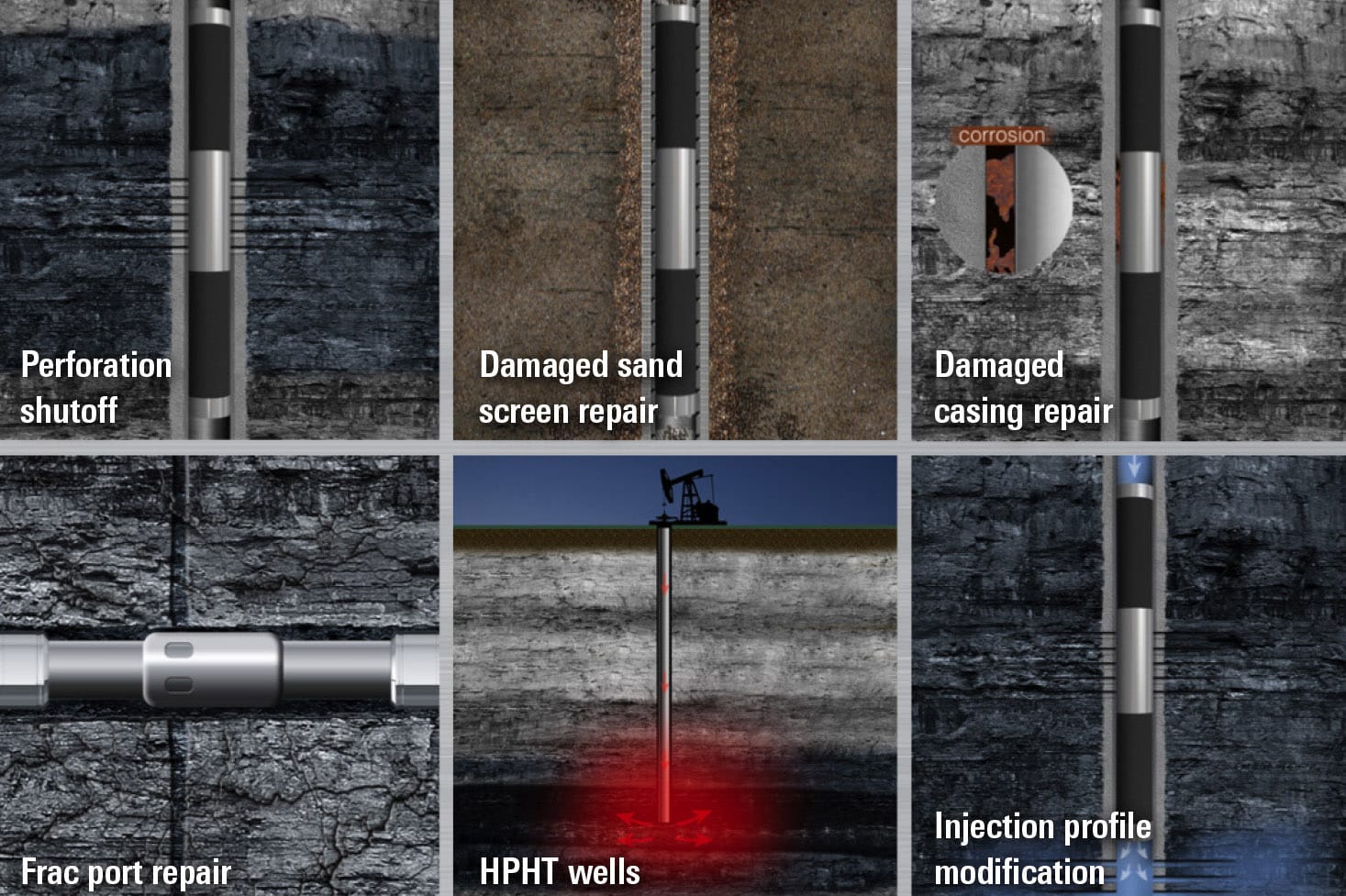

APPLICATIONS

- Repair casing, tubing, or screens

- Seal damaged frac ports and leaking differential valve tools, couplings, and sliding sleeves

- Close off perforations

- Shut off water, gas, or sand production

BENEFITS

- Provides virtually fullbore access to the well below

- Reduces time and costs by eliminating the need to pull and replace damaged casing or tubing

- Verifies the ID of the set patch in real-time, enabling immediate detection and correction of any anomaly

- Avoids sticking while running in hole because the high expansion ratio permits a smaller initial OD

- Seals effectively even in oval or out-of-gauge tubulars

- Minimizes risk of stuck setting tool with expansion from the top down

FEATURES

- Choice of materials for outer skin to ensure a good seal

- 21 stainless steel construction

- Ability to set in any diameter within its range

- Option to run a secondary patch through and set it below a previous patch