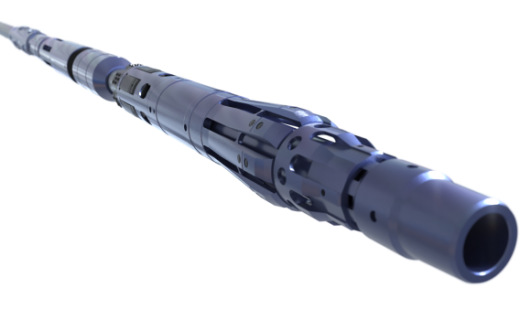

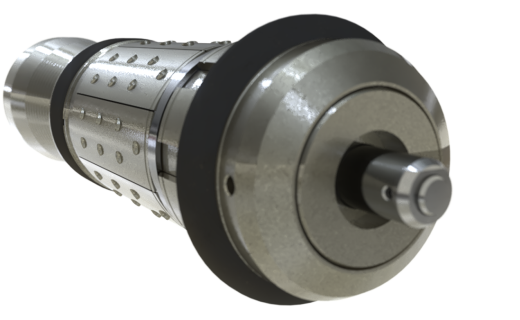

THE REACXION NANO DISSOLVABLE FRAC PLUG PROVIDES STELLAR PERFORMANCE WITH MAXIMUM RELIABILITY AND FASTER DISSOLUTION.

READY, SET… OVALITY

Don’t let its small size fool you. The Nano was engineered to be tough as nails to meet any completion head on – including those with ovalities. Unlike current plugs on the market, the Nano was designed specifically with casing ovalities in mind. Built from the ground up to set in deformations with individual fingers that conform to the casing, the Nano provides maximum grip and ultimate isolation for the most demanding scenarios.

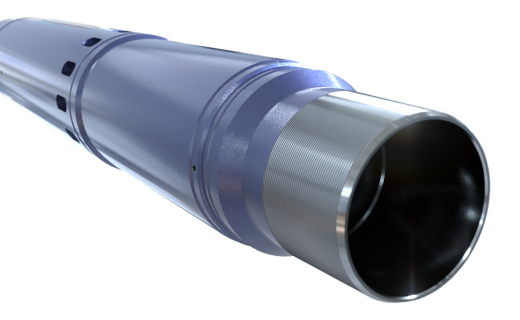

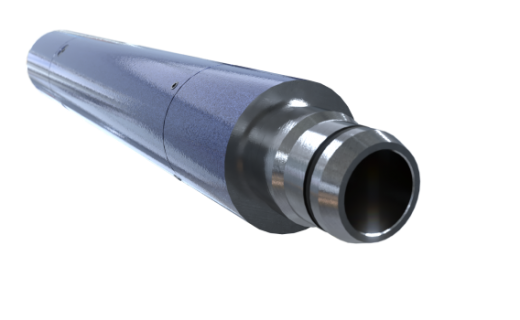

It’s design provides maximum fluid velocity past the element minimizing swabbing of the elastomer. This feature allows faster run times without compromising pressure or temperature integrity during setting. Conveyed via regular pump down operations, the plug can be set with conventional Baker style or similar setting tools. Ball in place or ball drop can be determined on location, allowing perfect flexibility with frac programs. The plugs proprietary coating allows it to be set in position hours prior to stimulation.

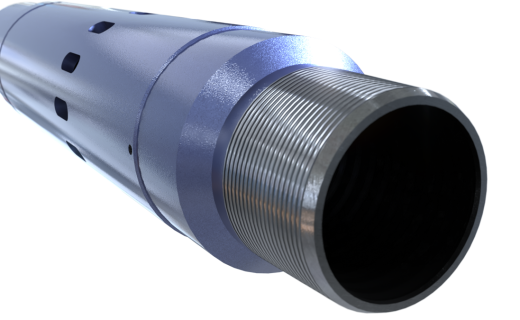

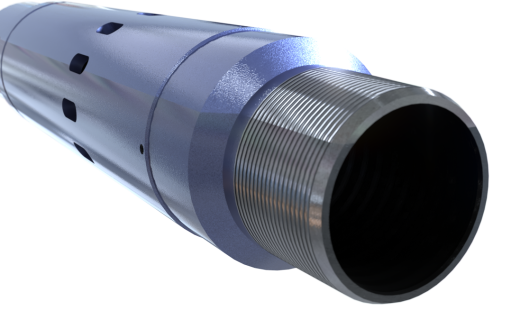

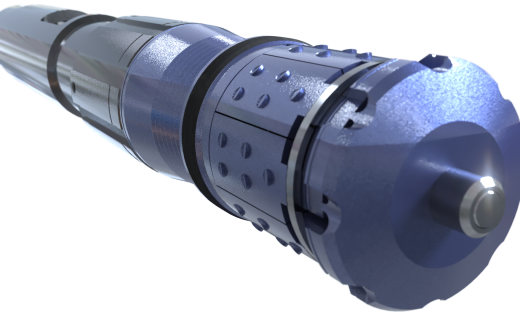

LOAD TRANSFER TECHNOLOGY

To achieve these results, the design combines expandable liner hanger and conventional pump down plug technologies. The design utilizes casing as a supporting member, transferring the load from the ball to the ball seat, through the slips and onto the casing. Pressure exerted on the ball during stimulation completes the setting operation while continuing to reinforce the integrity of the tool’s seal, forming a tighter seal as pressure is increased.

The tool contains less than one quarter the material of standard pump down plugs providing faster dissolution while decreasing wait times for full production. The load transfer technology allows the minimalistic design to be feasible. After use, the plug will dissolve in standard chloride solution or even very low-salinity fresh water, depending on plug material.

REPRESENTS THOUSANDS OF TESTING HOURS

We have tested over 2000 material coupons and almost 50 coatings to gain a comprehensive understanding of how dissolvable materials perform in the wellbore environment. We have used these learnings to optimize the design and materials of each ReacXion plug to ensure dissolution at the desired time. This has resulted in proprietary materials and coatings tailored for Bimodal dissolution (delayed) in low salinity and high salinity production environments.

FEATURES AND BENEFITS

- Can be set in casing ovalities

- Increased maximum fluid velocity past the element allows faster run times while minimizing element swabbing

- Simple WLAK increases efficiency

- Shorter degradation times due to less material

- Available in saltwater and fresh water dissolvable materials

- Fresh water degradable elastomer

- Ball in place or ball drop can be determined on location allowing for flexibility on frac programs

- Anti-preset design eliminates risk of premature setting during run in

- Proprietary coating allows the plug to be placed hours prior to seating the ball