THE REACXION COMPLETE FAMILY REPRESENTS THOUSANDS OF TESTING HOURS, RESEARCH AND DESIGN TO SOLVE THE UNIVERSAL PROBLEM OF DISSOLVABLE PLUGS NOT DISSOLVING IN YOUR WELLBORE ENVIRONMENT.

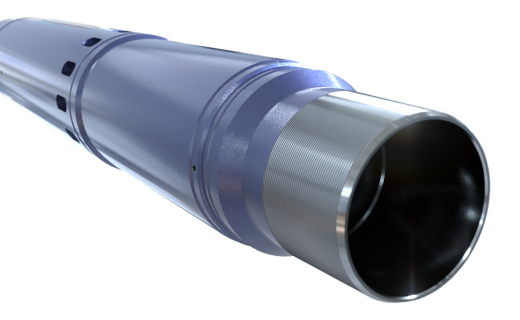

We have tested over 2000 material coupons and almost 50 coatings to gain a comprehensive understanding of how dissolvable materials perform in the wellbore environment. We have used these learnings to optimize the design and materials of each ReacXion plug to ensure dissolution at the desired time. This has resulted in proprietary materials and coatings tailored for Bimodal dissolution (delayed) in low salinity and high salinity production environments.

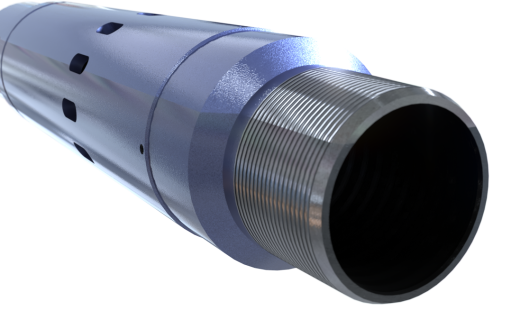

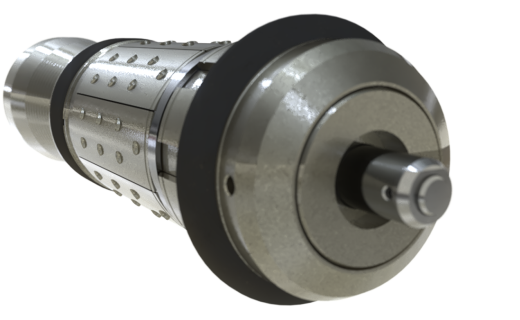

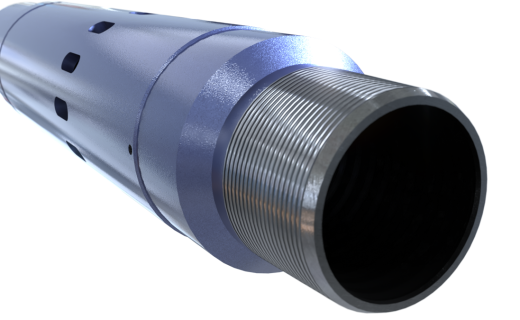

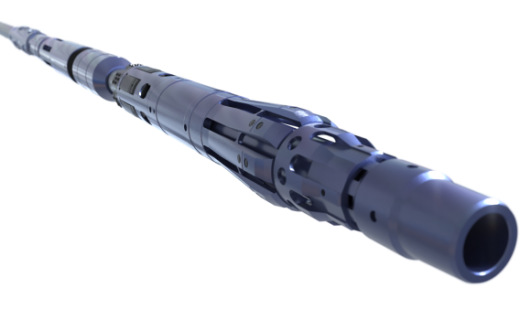

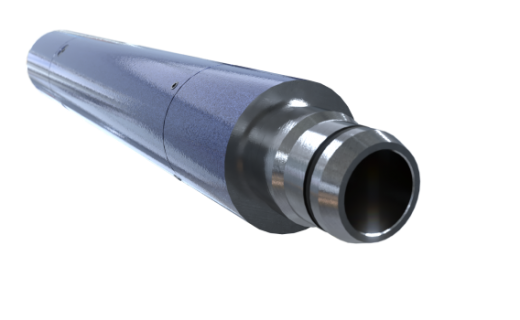

Lowest volume, largest surface area, and largest ID in its class The ReacXion Complete fully dissolvable frac plug enables immediate production and subsequently dissolves to deliver full bore production without milling. Conveyed as part of conventional pump down operations, the plug is set with standard industry setting tools. The plug boasts the shortest available length, offers the lowest volume of materials to dissolve while providing the largest ID in the industry, all of which facilitates dissolution and allows operators to bring their wells onto production sooner and with better results.

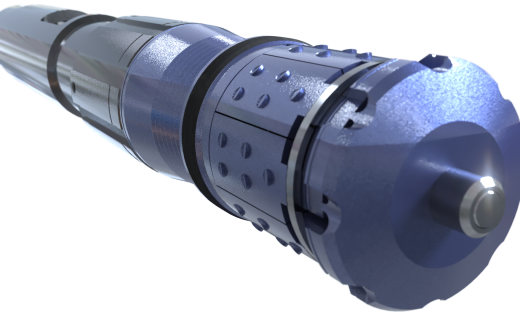

LOAD TRANSFER TECHNOLOGY

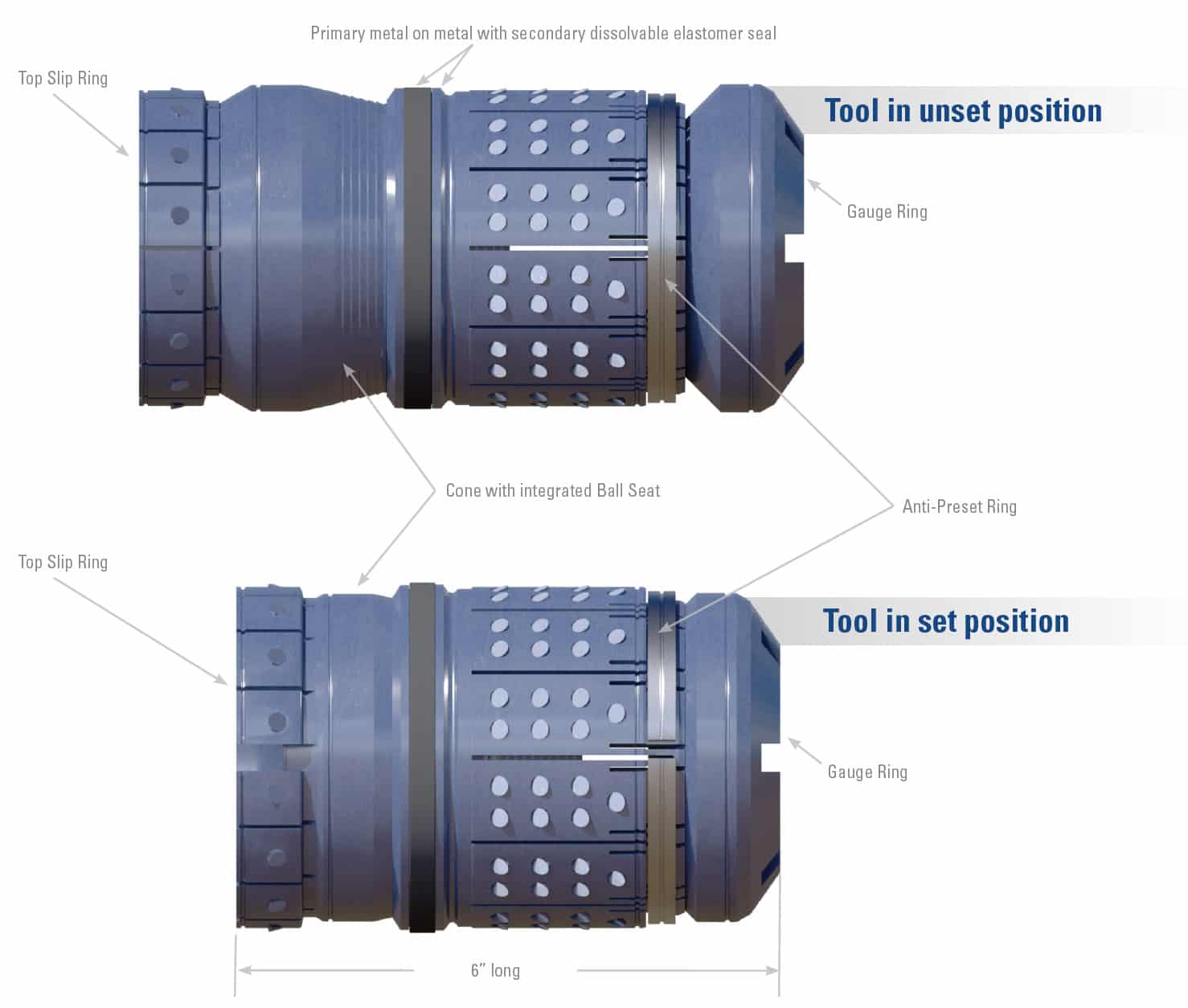

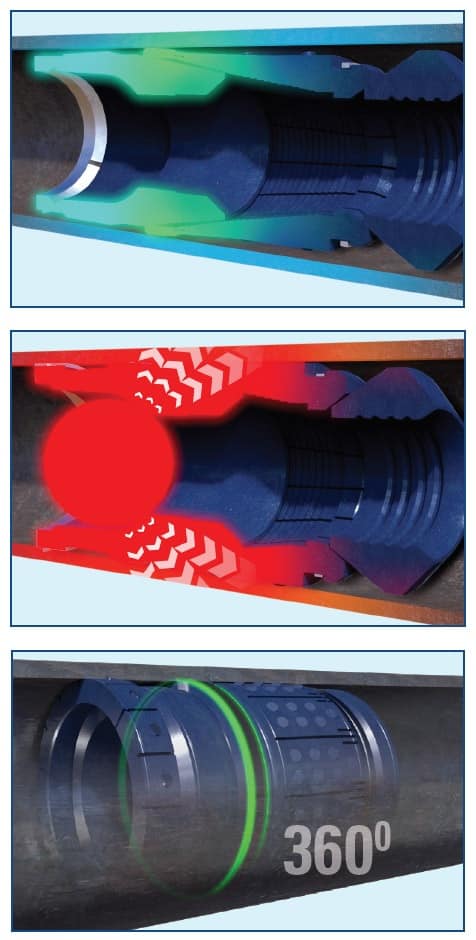

ReacXion Complete plugs utilize load transfer technology to provide compressive strength rather than conventional tensile strength to provide maximum mechanical sealing force. Using the casing as a supporting member, the load is transferred from the ball to the ball seat, through the slips, and onto the casing. Pressure exerted on the ball during stimulation continues to reinforce the integrity of the plug’s seal, forming a tighter seal as pressure is increased.

REACXION COMPLETE PROVIDES A PERFECT SEAL

ReacXion’s 360 Degree metal backup is made from a proprietary material with exceptionally high elongation allowing it to fully expand over the cone without breaking. The backup is engineered to accommodate non-conformities in the casing while providing a perfect seal. The primary metal and secondary elastomer seal constitutes less than 1% total volume of the entire plug yet achieves the highest pressure rating of any dissolvable.

A perfect seal is essential while spotting acid to ensure the integrity of the plug is not affected by the acid during operations.

BENEFITS

- Saves time and reduces costs during stimulation

- large plug ID enables immediate production

- dissolvable plug body and balls deliver fullbore production without milling

- Bi-Modal dissolution(delayed) ensures plug only dissolves in well effluent when desired

- Seal conforms to non-concentric casing for a perfect seal

- Increasing pressure on the ball improves seal integrity

FEATURES

- Largest available surface area and lowest material volume assures complete dissolution

- Proprietary coatings available enable plug placement several hours before seating the ball

- Low salinity, Medium Salinity and High salinity environments

- Metal on metal backup with secondary elastomer seal ensuring a complete seal

- Integrated ball seat with large overlap reduces risk of wash-out

- Small footprint

- Antipreset design that eliminates risk of pre-setting during RIH

- Tapered entry and exit for easy re-entry

- Dissolvable using industry standard chloride solution

APPLICATIONS

- Multistage plug-and-perf operations

- Isolation for refracturing operations