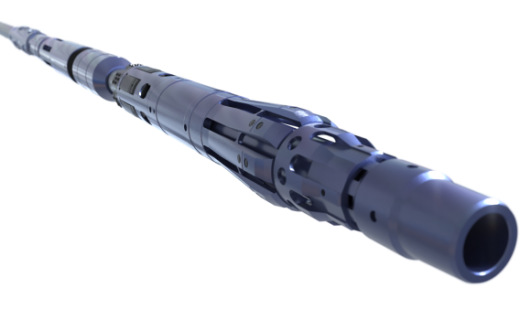

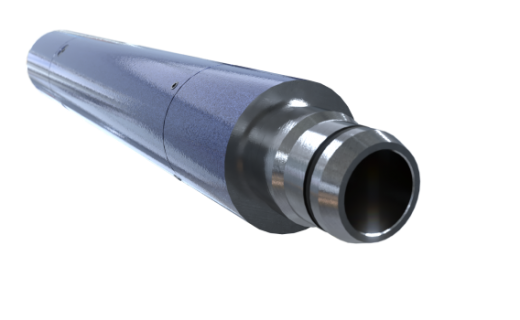

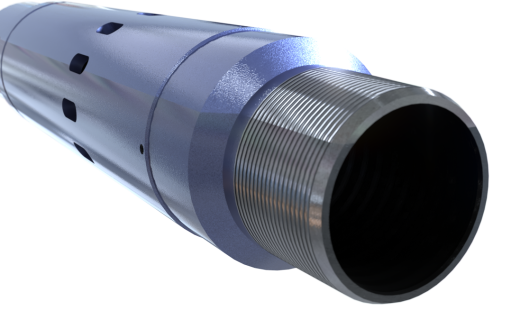

FRACXION UNITY INTEGRATED FULLY COMPOSITE FRAC PLUG COMBINES THE ADVANTAGES OF THE ULTRASHORT FRACXION MICRO FULLY COMPOSITE FRAC PLUG WITH AN INTEGRATED DISPOSABLE SETTING TOOL THAT EXPEDITES RIG-UP.

FRACXION UNITY INTEGRATED FULLY COMPOSITE FRAC PLUG COMBINES THE ADVANTAGES OF THE ULTRASHORT FRACXION MICRO FULLY COMPOSITE FRAC PLUG WITH AN INTEGRATED DISPOSABLE SETTING TOOL THAT EXPEDITES RIG-UP.

The technology streamlines multistage hydraulic fracturing operations while delivering unmatched reliability, with an impeccable track record of thousands of runs with zero misruns and zero NPT. Eliminating the need to redress the setting tool at the wellsite also minimizes the potential for human error. The setting tool is disposed of (e.g., with spent guns) after pulling it out of the well.

The setting tool and frac plug are factory-assembled using Six Sigma methodology for process improvement, resulting in 99.99997% reliability. No maintenance is required, and the self-bleeding setting tool contains no oil, reducing the exposure of personnel to pressurized tools. The setting tool firing head is reusable and equipped with a quick-change fitting.

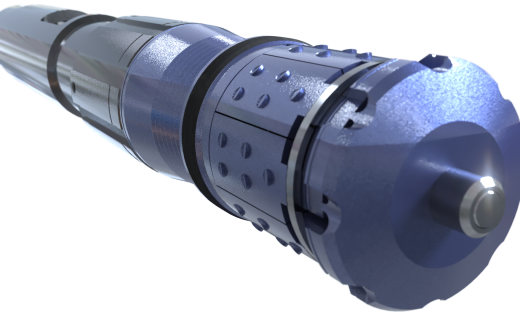

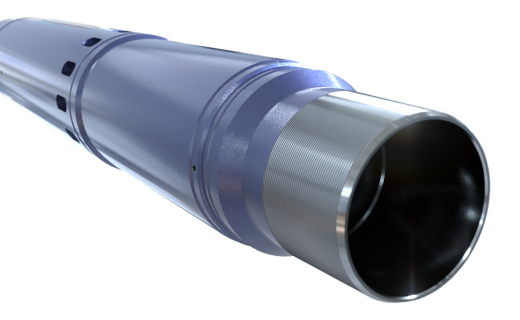

EXPEDITED MILLOUT AND REDUCED DEBRIS SIZE

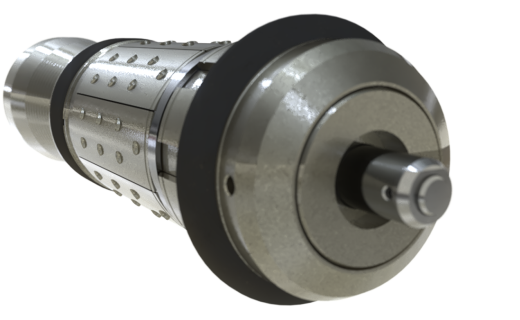

Based on our extensive experience with CT operations, the FracXion Unity plug is designed for milling out with minimum torque, generating small cuttings that are easily circulated out of the well. Special clutch features at the top and bottom of the plug prevent spinning between plugs during millout, reducing millout time.

The plug has hollow metal button slips that are engineered to shatter during milling. This feature and the reduced metal content improve millout time and decrease debris size even further.

BENEFITS

- Reduces operating time and HSE risk

- Uses smaller crane for rig-up and shorter lubricator

- Enhances reliability of plug setting

- Improves milling speed (4 min/plug on average) and reduces debris size

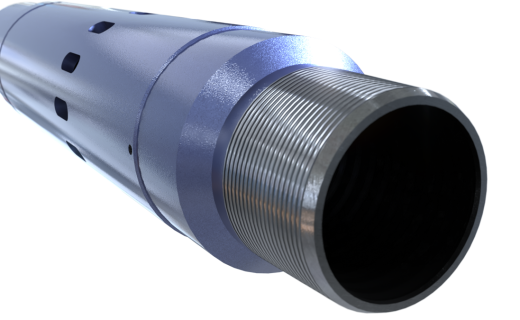

- Minimizes risk of presetting and incomplete setting

- Minimizes fluid costs and environmental impact when used with pumpdown ring

FEATURES

- Integrated disposable setting tool

- Proprietary angled anti-extrusion backup system that provides 360° element support

- Positive clutch engagement with lower plugs to facilitate quicker mill times

- Optimized slip material and design to minimize the amount of hardened material and improve milling time

- Engineered elastomer that mills into small pieces, not long strips

- Proprietary slip design to keep buttons from chipping and plugs from slipping

- Range of setting options: wireline, coiled tubing, or threaded pipe

- Integrated shear ring design that eliminates wellsite installation of shear screws

APPLICATIONS

- Zonal isolation in hydraulically fractured vertical, deviated, and horizontal wells