REDUCE METAL CONTENT FOR FASTER MILLOUT AND MINIMAL DEBRIS SIZE.

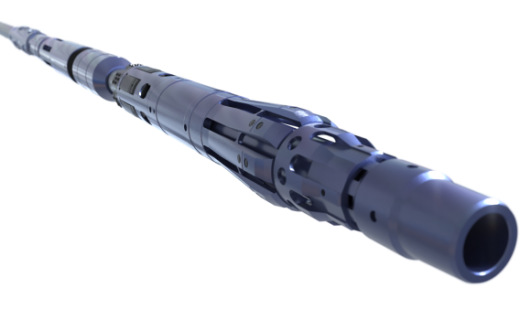

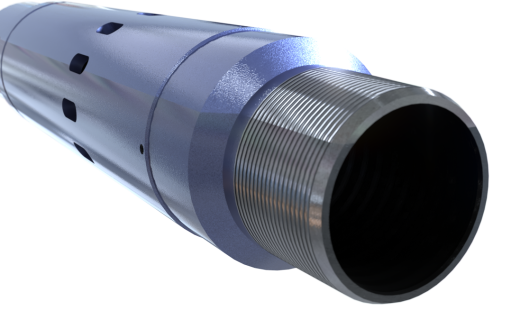

Accelerate your time to production with FracXion Micro fully composite frac plugs that reliably isolate zones in vertical, deviated, and horizontal wells during plug-and-perf operations and minimize milling time.

Based on our extensive experience with CT operations, FracXion Micro plugs are designed for milling out with minimum torque, generating small cuttings that are easily circulated out of the well. The plugs have

hollow metal button slips that are designed to shatter during milling, which reduces metal content and debris size.

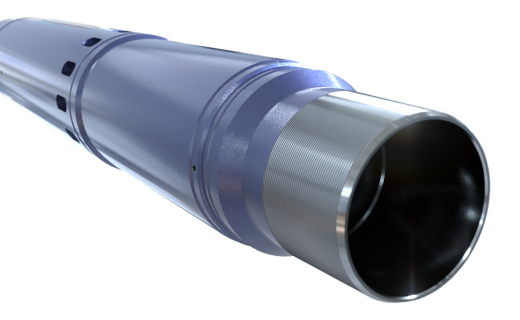

Special clutch features at the top and bottom of the plug prevent spinning between plugs during millout, reducing millout time.

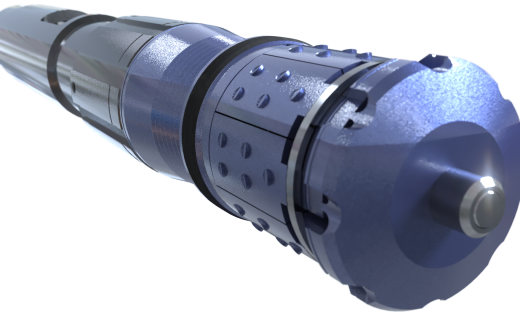

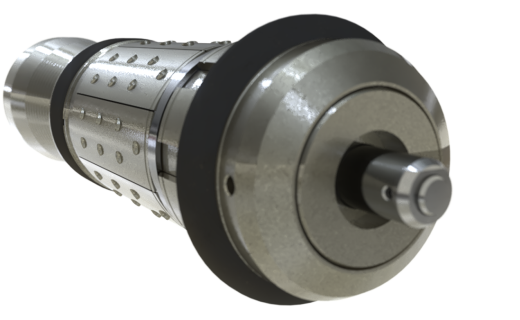

INCREASE RUN-IN SPEEDS WITH CONFIDENCE

Antipreset measures also provide an industry-leading design that increases confidence at higher run-in-hole speeds.

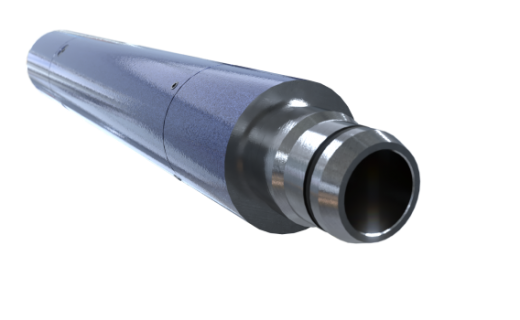

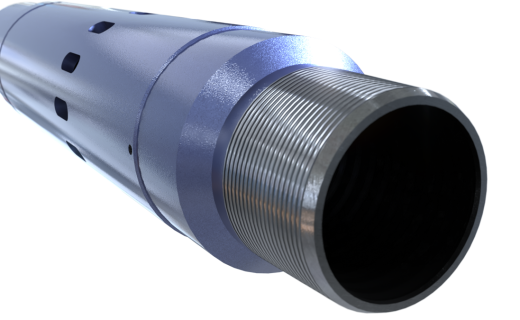

Set using wireline, CT, or threaded pipe, FracXion plugs incorporate a one-way internal check valve that is closed with a ball while the zone above the plug is fractured. The plug can be run with the ball in place or the ball can be dropped from the surface when the plug is in position. The check valve allows free flow of fluids from below the plug after stimulation.