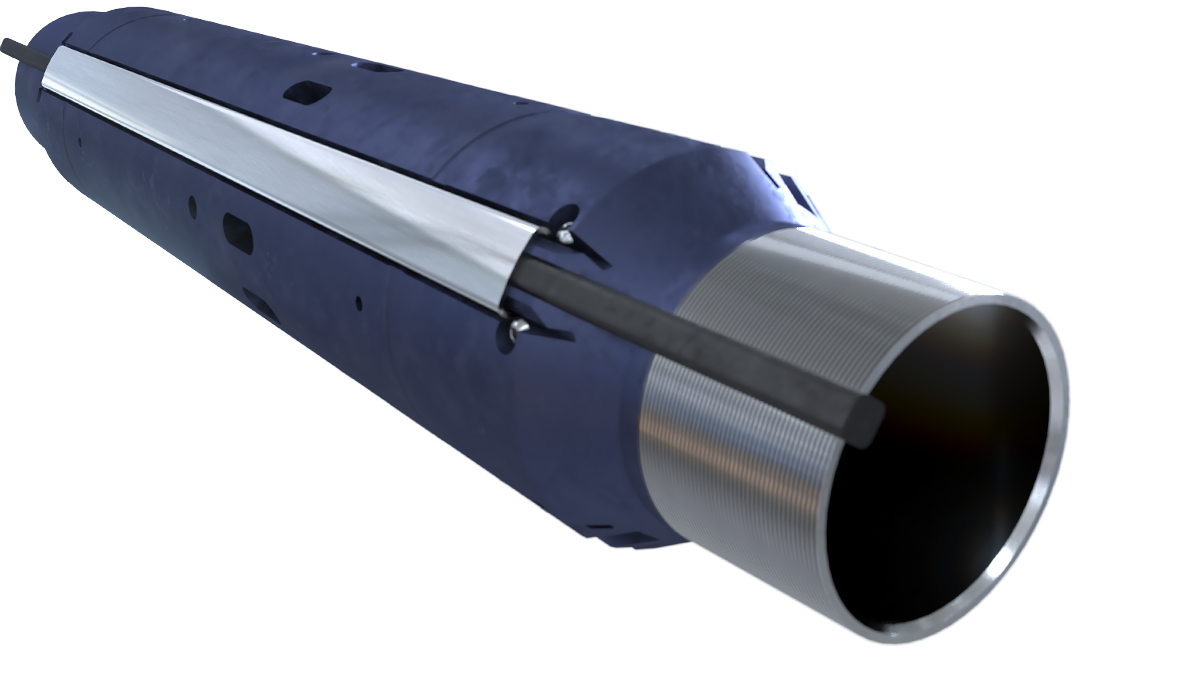

THE DTS/DAS FRACTURING SLEEVE IS BUILT ON THE SAME SOLID FOUNDATION AS OUR PROVEN PRECISION RE-CLOSABLE CT HYDRAULIC FRACTURING SLIDING SLEEVE TECHNOLOGY.

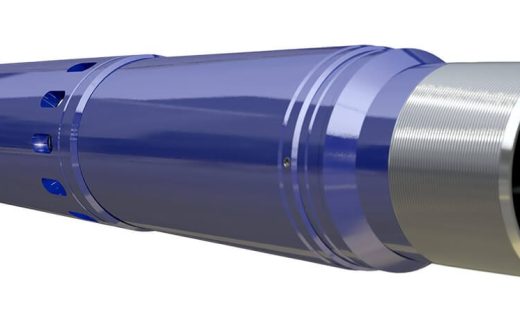

Engineered as an effective means to provide real-time data feedback to the operator, the DTS/DAS distributed fiber optic sensing is offered as a way to add valuable data during stimulation and the remaining life of the well.

SELECTIVE SLEEVE ACTIVATION

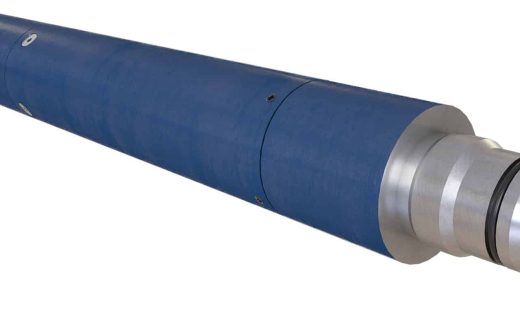

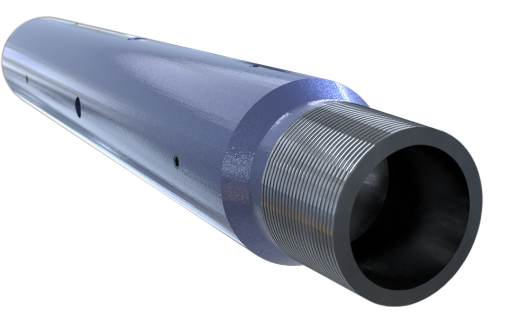

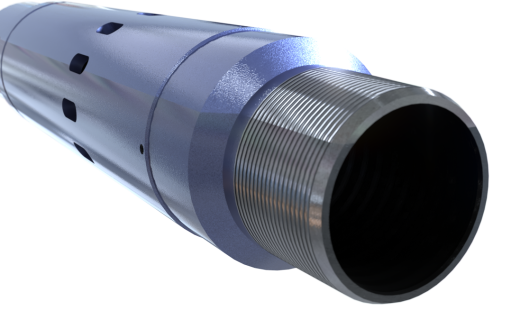

This robust fracturing system was constructed for use in cemented or open-hole environments. Designed to allow operators to perform selective single-point multistage fractures, the sleeve is a two-position, full bore, fracturing sleeve designed for high-pressure and high-rate fractures.

The inner sleeve can be run using a pinned configuration and is sheared when desired, providing a positive indication the specified port has opened before fracturing. In addition, the sleeve utilizes an adjustable detent locking system that locks the sheared sleeve to prevent accidental manipulation. The sleeve is opened using our CT fracturing sleeve shifting tool.

One of the shortest sleeves available, at under 3 feet, DTS/DAS sleeves do not require the use of pup joints and can be pre-bucked on the casing or even installed on the rig floor. This sleeve system allows for safer handling at the well-site, easier installations, even in wells with moderate dog leg severity, and ultimately, improved efficiency in the completion of the well.

RELIABLE DATA PROTECTION

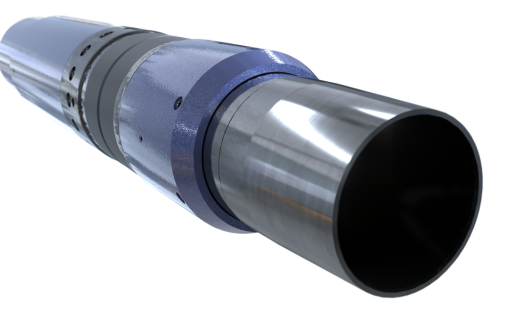

Engineered to provide reliable protection, the DTS/DAS channel protects the data cable as it is run and cemented in place. Offering 2’ length protection and 45-degree radial protection from induced erosion, the channels are designed to allow near 360-degree coverage during frac initiation.

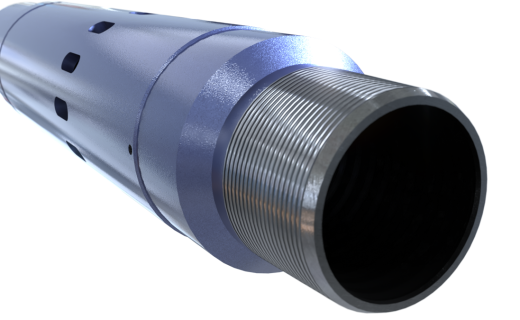

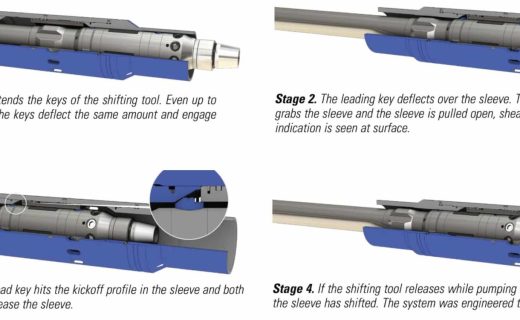

POSITIVE SLEEVE ACTUATION

The shifting tool that actuates the sleeve is compact (2.5 ft long [0.8 m]), featuring a self-centralizing design with a 10,000-psi [69-MPa] pressure rating, and individual hydraulically controlled key sets ensure maximum performance during actuation up to 35,000 lbf [155,687 N] of over-pull without releasing from the sleeve unless desired.

The shifting tool has been engineered as a fracture-in-place solution with no requirements for isolation or related service tools, even after hundreds of stages are fractured. The fully compartmentalized and hydraulically balanced design with multiple layers of solids control ensures that no solids will interfere with the tool’s operation.

FAIL-SAFE OPERATION

The shifting tool, in combination with the cemented fracturing sleeves’ adjustable shear pinned sleeve option, provides operators with a reliable surface indication of when a sleeve has shifted open, determined by positive indication on the weight indicator combined with the release of the shifting tool. The shifting tool is designed to release from the sleeve when actuated, only once the sleeve has shifted, or once the operators have stopped pumping.

BENEFITS

- Real-time data feedback

- Simplifies rig operations

- Enables reliable zonal shutoff

- Recommended for re-closable operations

FEATURES

- Sleeve for cemented and openhole completions uses CT to open and close sleeves

- DTS/ DAS channel provides 2’ length and 450 radial protection from induced erosion

- Large flow port area ensures access to fracture planes

- Fullbore has no effect on cementing or reentry for subsequent stimulation

- Reliable shifting tool technology provides positive sleeve actuation

- Shifting tool is fail-safe opening and closing; only releases if the operator stops pumping or if the sleeve shifts

- Short length of sleeve facilitates handling and installation

- Short valve sleeve travel ensures long term manipulation

APPLICATIONS

- Cemented multistage stimulation with single-entry fracture placement

- Openhole multistage stimulation, deployed with openhole packers

- Where Real-Time Data Feedback is desired