MINIMIZE RISKS OF PRESETTING AND PLUG MOVEMENT DURING MULTISTAGE FRACTURE STIMULATION.

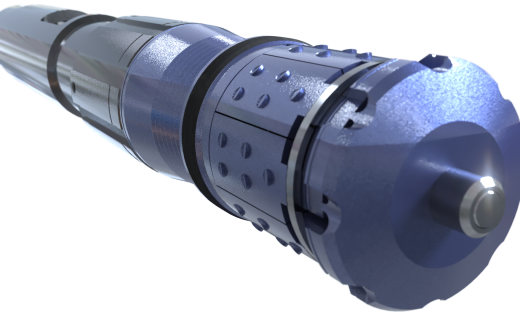

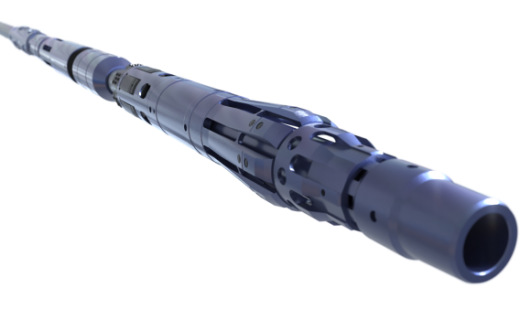

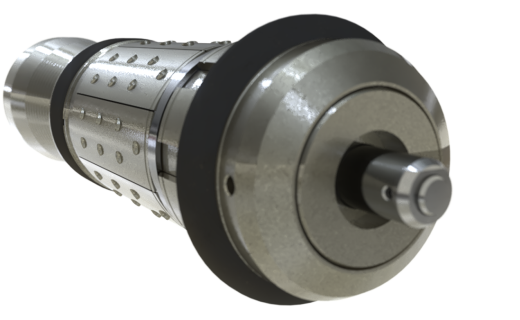

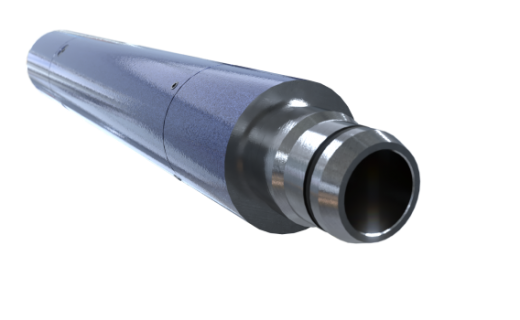

Isolate zones during multistage plug-and-perf fracture stimulation using the Copperhead drillable bridge and frac plug. Engineered antipreset features reduce your risks and costs while running using wireline, coiled tubing, or threaded pipe. The solid core also enables the plug to hold pressure from both directions, even under multiple pressure and temperature cycles.

ADD FLEXIBILITY, AND FLOW BACK AFTER FRACTURING

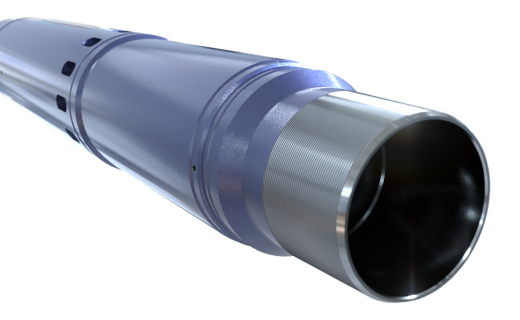

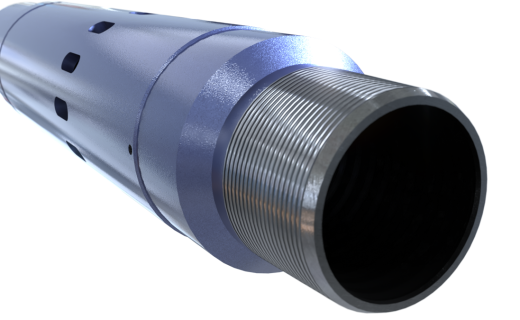

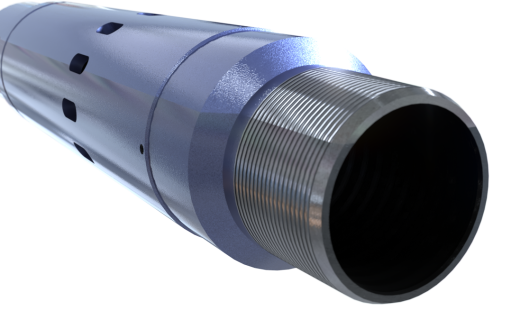

The plug features nondegradable aluminum material and incorporates a one-way, internal check valve that is closed with a ball while the zone above the plug is fractured. The plug can be run with the ball in place, the ball can be dropped from surface after positioning the plug, or a caged-ball configuration can be used. The check valve enables free flow of fluids from below the plug immediately after stimulation. Plug design also facilitates rapid milling both by preventing slipping or spinning and by milling into small cuttings that can be easily circulated out of the well.

INTELLIGENT CONSTRUCTION

The bridge plug has a solid core that allows it to hold pressure from both directions. The frac plug features a one-way, internal check valve that is closed with a ball while the zone above the plug is fractured. The plug can be run with the ball in place, the ball can be dropped from the surface when the plug is in position, or a caged-ball configuration can be used. The check valve allows free flow of fluids from below the plug after the stimulation operation is completed. Plug components can be quickly drilled out with the Copperhead plug mill into small, consistently sized cuttings that are easily circulated out of the well.

APPLICATIONS

- Vertical, deviated, and horizontal wells

- Zone isolation during multistage stimulation to use

BENEFITS

- Eliminates presetting and withstands multiple pressure reversals to reduce rig time and costs

FEATURES

- Nondegradable aluminum material

- Unique activation system to maintain a superior seal even under multiple pressure and temperature cycles

- Proprietary slip design to keep wickers from chipping or cracking in hard steel casing and slipping in softer steel casing

- Element backup system to keep rubber element locked in place with no extrusion

- Rotational lock mechanism to prevent slipping or spinning during removal

- Positive engagement clutch to prevent spinning of bottom sub on top of the next plug in multiple-plug drill out