COMPLETE PROFILE CONTROL

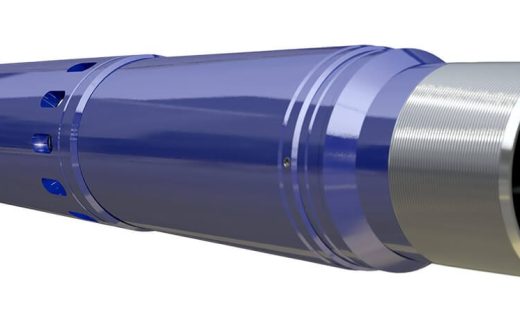

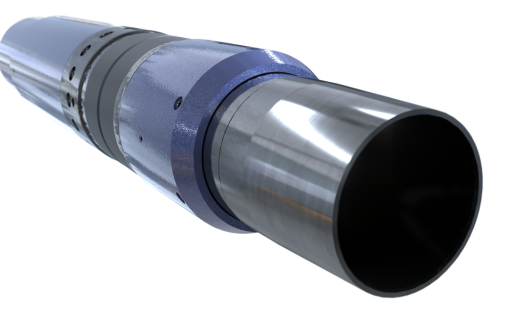

The DropShift System was designed to work with our industry-leading Harrier shifting tool and Eco-X packer. After mill out, the Harrier is used for unlimited opening and closing of each sleeve in the event of water encroachment or other wellbore issues, greatly increasing the life cycle of the well while providing complete profile control. The Eco-X packer provides reliable isolation in a tool small in size but big in performance.

THE DROPSHIFT ADVANTAGE

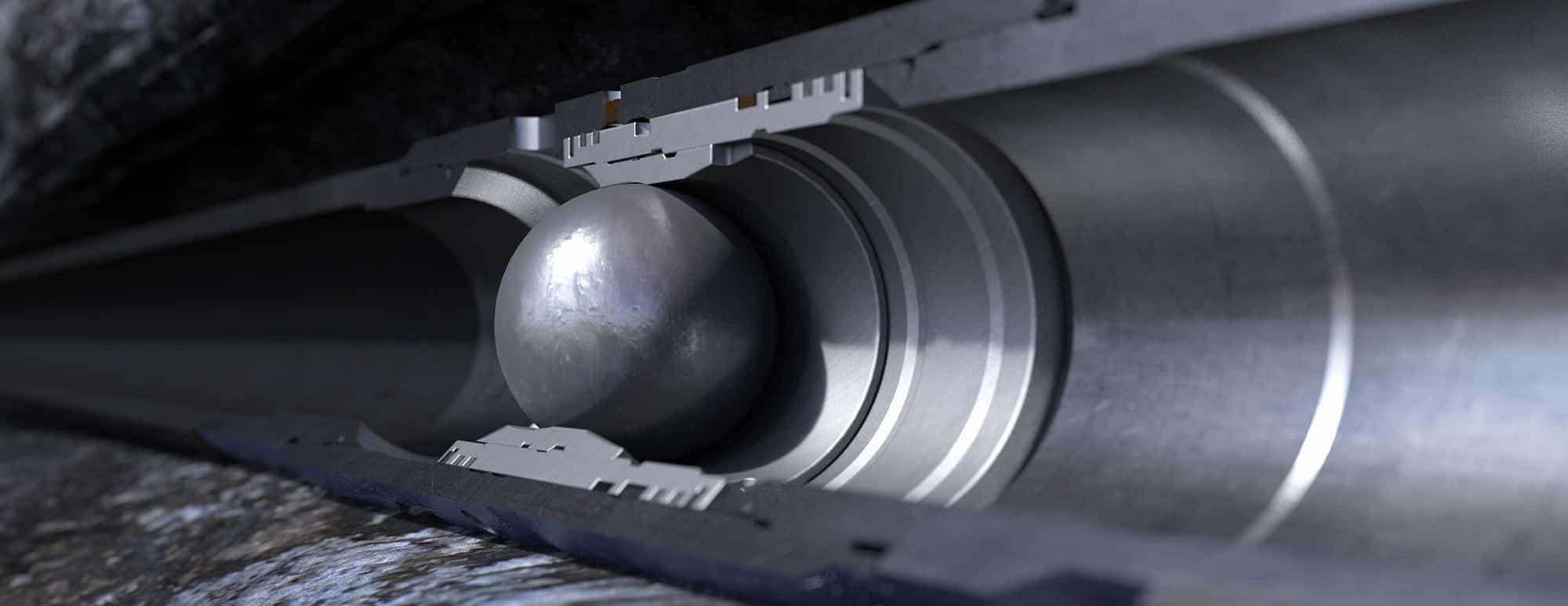

Sequentially fracture the wellbore with progressively larger balls

Selectively shift sleeves with CT after mill out for complete profile control

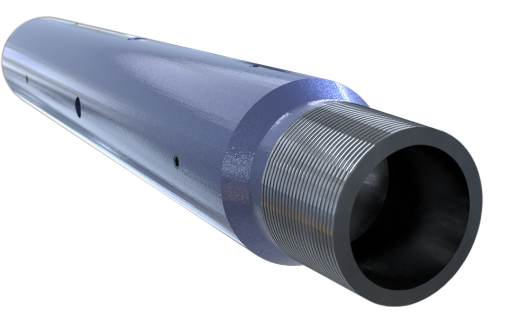

Lightweight and easy to handle

INCREASE PRODUCTION AND MAXIMIZE RECOVERY

The DropShift System maximizes production and recovery by ensuring every interval is stimulated. Re-closable frac sleeves allow zonal shutoff after fracturing for complete profile control of water-producing zones, re-stimulation, and other re-work.

CONFIGURE AND CONTROL

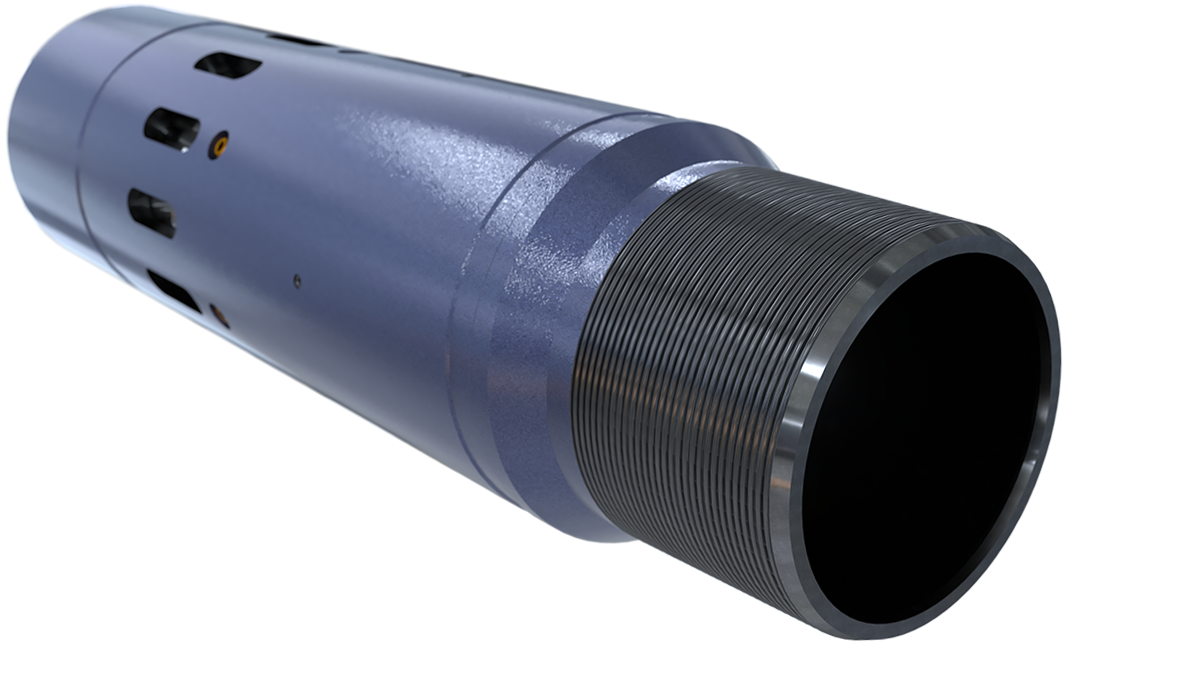

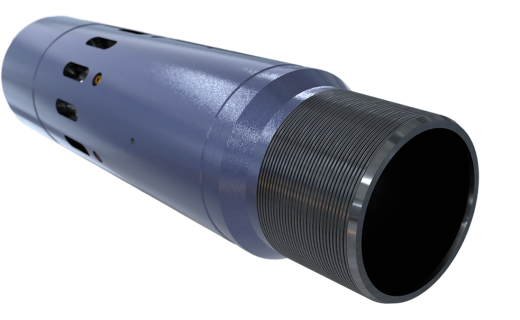

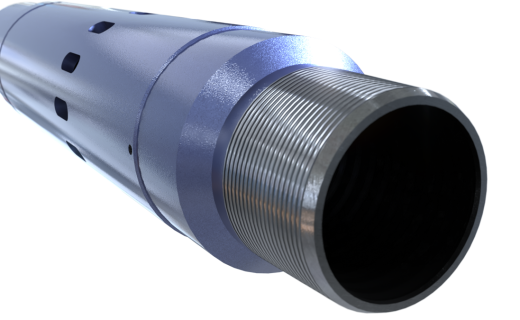

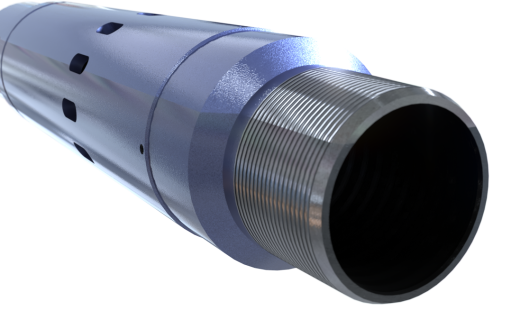

With its short length, the DropShift is lightweight and easy to handle. Large ports maximize stimulation rates while proprietary alloys ensure ball seats are easily milled out. The DropShift sleeve is available in P110, L80, and other materials with API, Premium, or Semi-Premium Threading.

FEATURES AND BENEFITS

- Continuous pumping operations

- Deploy in cemented and open hole applications

- Re-closable frac sleeves for zonal shutoff after fracturing

- Anti-rotational device for easy mill out of balls and seats

- High rate fracturing

APPLICATIONS

- Open-hole and cemented multi-stage stimulation

- Multistage fracturing

- Matrix acidization treatment